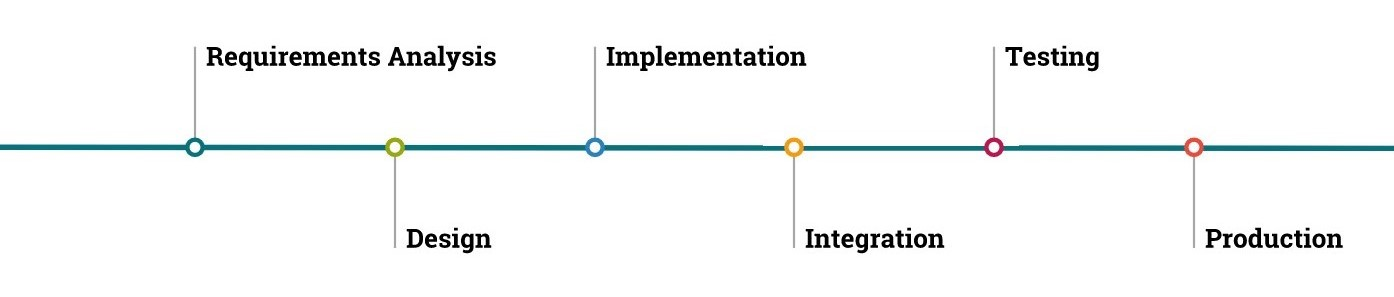

1. Requirements Analysis: Derive requirements from official game rules, the Q & A, and the Generic Kit Usage Guide.

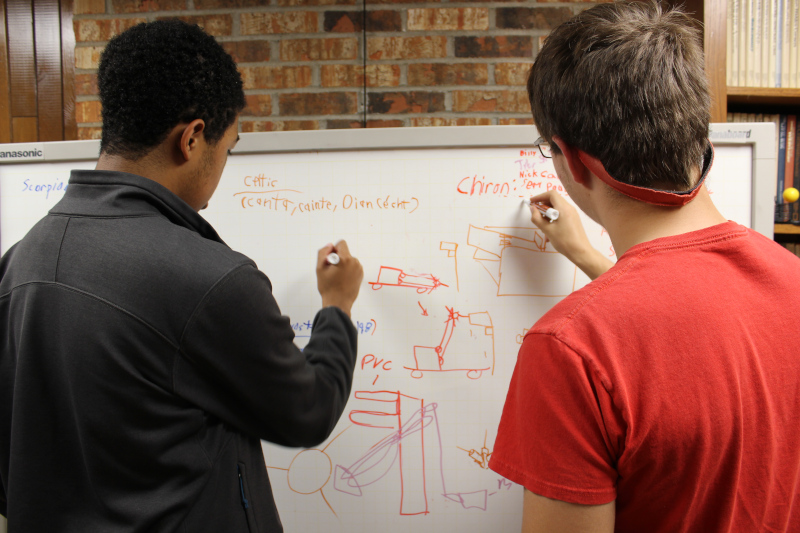

2. Design: Brainstorm, prototype, perform alternatives analysis, and finalize the design.

3. Implementation: Model the design in Computer Aided Design (CAD) using Fusion 360 and Tinker CAD, then 3D print parts and make initial CNC cuts.

4. System Integration: Make final precision CNC cuts, complete robot assembly, and program the robot.

5. Verification and Validation: Test at each step of the engineering process from design to production.

6. Production: Make modifications based on game day performance and market the robot.